Hakko FT-710. Rotary Tip Cleaner

Цена - по запросу

- Производитель: Hakko

- Модель: FT-710

- Наличие: Нет в наличии

- Solder-splash-preventing rotary tip cleaner

- Level of solder removal can be adjusted using two different types of brushes. It also reduces the oxidation of tips

- Brushes can be replaced without using any tools, and safe design prevents solder wastes from entering drive part

| Tip cleaner having both wire-type and sponge-type advantages | |

| Prevents solder from splashing when cleaning. |

| · Inserting just the tip into the receptacle completely prevents solder from splashing. | |

| |

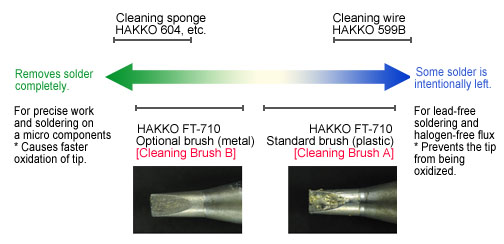

| Two-types of brushes control how much solder is removed. |

| · Solder removal status can be adjusted by plastic brushes and metallic brushes. | |

| With wire-type cleaners, excessive amounts of solder remain on the tip, which causes solder to splash when soldering. With sponge-type cleaners, oxidation is promoted, which causes shorter tip life. · A tip cleaner with both wire-type and sponge-type advantages eliminates the above problems when soldering. | |

| Comparison of how much solder is removed by the different cleaning methods< | |||

| * The photos show the iron tips T12-D24. | |||

Enlarged images of cleaning brushes | |||

| Minimizes decrease in temperature of the tip while cleaning. | |

| · Inserting the tip turns the brush automatically; no need to switch it on and off. · Reduces the tip cleaning time between soldering works to increase work efficiency. · The electric rotary cleaner provides a uniform final cleaning status with no differences between individuals. | ||

| Comparison of decrease in tip temperature by cleaning method | |||||||||

| If decrease in temperature is small, the time for a single cleaning also becomes short. Because cleaning is performed many times per day, the overall working time can be also shortened. | |||||||||

| Time for single cleaning (The time for a single cleaning is measured as the time until the tip temperature reaches the set temperature after cleaning.) | |||||||||

| |||||||||

| The low-noise design relieves stress due to noise during work. | |

| * This cleaner is very quiet in comparison with competitor's electric tip cleaner. | ||

| Easy to maintain |  |

| · Easy-to-replace brushes | ||

| → Brushes can be replaced without removing any screws. | ||

| · Solder left inside is stored in "Solder waste collector". | ||

| → Solder does not splash all over the inside of the main body. | ||

| · Safe design prevents brushes from turning unexpectedly during replacement. | ||

| → The brush cannot be replaced unless the AC adapter is unplugged. | ||

| This tip cleaner can be attached to HAKKO iron holders HAKKO FH-101, FH-200 and FH-201. | |

| · This tip cleaner can be attached to any of the above 3 iron holders using just 2 screws. For other iron holders, this tip cleaner can be placed next to the iron holder. | ||

| * The HAKKO FT-710 itself cannot be used as an iron holder. Be sure to use it together with an iron holder. |

| Category | Title |

| How to use | Cleaning mechanism |

| How to use | How to ground the HAKKO FT-710 |

| How to use | Combinations of the HAKKO FT-710 and iron holders |

Packing List

| * Some soldering irons or tip shapes are NOT available. Please check 'Specification' if your soldering iron or tip shapes are available. |

| Part No. | Packing List |

| FT-710 | HAKKO FT-710, AC adapter, Receptacle A and B, Lock nut, Solder waste collector, Gauge, Instruction manual |

| NOTE: Optional Part Receptacle C being purchased, HAKKO 917(Discontinued) (Station HAKKO 938(Discontinued)) and HAKKO FX-8301(Station HAKKO FX-838) are also available. |

Specifications

| Model No. | FT-710 |

|---|---|

| Rating | DC 24 V 130 mA |

| Brush rotational speed | 2,500rpm |

| Standard receptacle | Receptacle A and B |

| Dimensions | 71(W)×77(H)×107(D) mm |

| Weight | 450g |

・AC Adapter

| Output voltage | DC 24 V |

|---|

| Applicable Soldering Iron List |

| Receptacle | Soldering tip | Unusable shape | Custom-ordered shape | Soldering iron |

| Receptacle A | T7 series | T7-JL02 Spatula | T7-KF | HAKKO FM-2027 Station: HAKKO FM-202 (Discontinued) |

| T11 series | - | - | HAKKO FX-901 | |

| T12 series | T12-JL02 Quad Tunnel Spatula | T12-WB2 T12-WD08 T12-WD12 T12-WD16 T12-WD52 T12-WI T12-DL52 T12-KF | HAKKO FM-2027/2028 for Japan, Oceania, Asia & Other countries Station: HAKKO FM-203, HAKKO FX-950, HAKKO FX-951, HAKKO FX-952, etc. | |

| T15 series | T15-XD15 T15-JL02 T15-JD14 T15-JD16 T15-R48 Quad Tunnel Spatula | T15-1603 T15-1605 T15-BC15 T15-BC28 T15-CF2 T15-CF3 T15-SB03 | HAKKO FM-2027/2028 for North America & EU. Station: HAKKO FM-203, HAKKO FX-950, HAKKO FX-951, HAKKO FX-952, etc. | |

| Receptacle B | T14 series | - | - | HAKKO 957 (Discontinued) |

| T18 series | - | - | HAKKO FX-8801 Station: HAKKO FX-888 (Discontinued), HAKKO FX-888D | |

| T34 series | - | - | DASH:FX-650 series | |

| 900 M series | 900M-T-H 900M-T-1.8H | 900M-T-LB 900M-T-1.2LD | HAKKO 900 Type Medium HAKKO 907 Station: HAKKO 928 (Discontinued), HAKKO 936 (Discontinued), HAKKO 937 (Discontinued) etc. | |

| Receptacle C (Optional Part) | T10 series | - | T10-J02 T10-K T10-KL T10-KU T10-LB T10-LI | HAKKO 917 (Discontinued) Station: HAKKO 938 (Discontinued) |

| T13 series T17 series | - | - | HAKKO FM-2026 Station: HAKKO FM-203, HAKKO FX-950, HAKKO FX-951, HAKKO FX-952, etc. | |

| T20 series | - | T20-K T20-KU T20-BL T20-BL2 T20-BL3 | HAKKO FX-8301 Station: HAKKO FX-838 | |

| T22 series | - | T22-C3 T22-BL T22-BL2 T22-D45 T22-J02 T22-K | HAKKO FM-2030, HAKKO FM-2031 Station: HAKKO FM-206 | |

| Receptacle, custom-designed | T19 series | - | - | HAKKO FX-8805 Station: HAKKO FX-889 |

| T33 series | T33-BC2 T33-BC3 T33-BC4 T33-BC5 T33-BC6 T33-D24 T33-D32 T33-D5 T33-D6 T33-1610 T33-1611 | T33-SSBC2 T33-SSBC3 T33-SSBC4 T33-SSBC5 T33-SSD24 T33-SSD32 T33-SSD16 T33-SSD6 T33-SS1610 T33-SS1611 | HAKKO FX-8802 Station: HAKKO FX-801 | |

| PRESTO series | - | - | HAKKO PRESTO |

| *Soldering iron other than listed above (HAKKO FX-100, HAKKO FM-2032, Built-in solder feed type, Nichrome heater type and HAKKO 455/456), and Desoldering / Rework are not available. |

Replacement parts

| Part No. | Name | Specifications | |

|---|---|---|---|

| B3523 | Lock nut | |

| B3517 | Receptacle A | |

| B3518 | Receptacle B | |

| A1566 | Cleaning brush A (plastic brushes, qty 2) | |

| B3521 | Solder waste collector | |

| B3520 | Pulley belt |

|

| *Some soldering irons and tip configurations cannot be used with receptacles A/B. Be sure to confirm applicable soldering irons and tip configurations from the applicable soldering iron list. |

| * Optional Part Receptacle C being purchased, HAKKO 917 (Station HAKKO 938) and HAKKO FX-8301(Station HAKKO FX-838) are also available. |

Options

| Part No. | Name | Specifications | |

|---|---|---|---|

| A1567 | Cleaning brush B (metal brushes, qty 2) | |

| B3519 | Receptacle C |

*Some soldering irons and tip configurations cannot be used with receptacles A/B.

Be sure to confirm applicable soldering irons and tip configurations from the applicable soldering iron list .

Maintenance

| Category | Title |

|---|---|

| How to use | Cleaning mechanism |

| How to use | How to ground the HAKKO FT-710 |

| How to use | Combinations of the HAKKO FT-710 and iron holders |

| Maintenance | Day-to-day cleaning |

| Maintenance | Maintenance and replacement frequency of the cleaning brush |

| Maintenance | Why can no solder be removed? |

Video

| Preview | Title |

|---|---|

| how to clean a tip |

Гарантия

У нас вы можете получить онлайн-консультацию по выбору и комплектации, инструмента.

Обмен и возврат товара осуществляется в соответствии с положениями Закона о защите прав потребителей. Адрес точки приёма: 192019, г. Санкт-Петербург, ул. Смоляная, д.15, лит. А, пом. 24.

- Информация о гарантии производителя

- Найти сервисный центр по ремонту инструмента

- Сертификаты продавца/производителя

ETK-79303